Production Metal Stampings

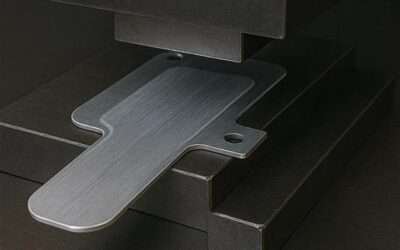

Production Metal is a supply chain partner for metals and plastics manufactured components for the Hurricane shutter industry, boat tower and boat lift manufacturers as well as FDOT handrail and bike and pedestrian guardrail components. We develop and build punching equipment for the tracking systems used in solar fields. We also offer general machining services for local industrial manufacturing and machinery maintenance.

In-House Ability

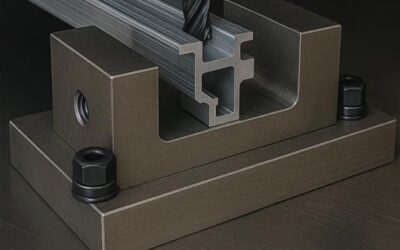

Production Metal will work with you towards the design and development of your prototype and as a trusted partner for your supply chain manufacturing requirements. We offer value-added secondary operations of machining, punching, forming, and welding as well as general progressive stamping and CNC production. Our machining department designs and builds tooling to punch the flange and web of steel H beams used in the solar field tracking systems.

Our design staff works with the following formats DXF, DWG, IGS …

TOP QUALITY

Quality control, product improvement and customer involvement are the key forces behind our continued growth as we strive to manufacture products that exceed your expectations

Processing Capability of 30ft.

Processing Aluminum extrusion of 20 – 42 feet is one of our specialties.

With multiple CNC Mill and Punch presses fitted with accurate and repeatable servo feed units allows continuous machining and punching

lengths of aluminum flat bar or special shaped extrusions up to 42 feet in length.

Our automated aluminum extrusion saws supply CNC Mill, CNC lathes and punch presses for volume production of cut to length product.

News

Here are some of our latest news…

CNC Punching in Florida: Precision Fabrication with CNC Punch Presses & Metal Punch Services

What Is CNC Punching? A Guide to Precision Sheet Metal Fabrication in Florida CNC punching is a cornerstone of modern manufacturing, enabling businesses across Florida to create precise, high-quality metal components efficiently. From aerospace parts in Tampa to...

How to MIG Weld Sheet Metal in Florida

How to MIG Weld Sheet Metal: A Florida-Friendly Guide MIG welding is a go-to method for fabricating and repairing sheet metal in Florida’s bustling automotive, marine, and construction industries. However, welding thin metal (like 16–24 gauge) demands precision to...

Aluminum Welding in Florida: How to Choose the Best Method for Weldable Aluminum

Aluminum Welding in Florida: How to Choose the Most Suitable Method Aluminum is a cornerstone of Florida’s marine, aerospace, and construction industries due to its lightweight, corrosion-resistant properties. However, welding aluminum requires specialized techniques...

Stamping Tools in Florida

Stamping Tools: Complete Solutions for All Metal Types in Florida From automotive parts to aerospace components, metal stamping plays a vital role in Florida’s manufacturing sector. This process transforms flat metal sheets into precise, complex shapes using...

Top Metal Stamping Companies in Florida

Florida’s Metal Stamping Experts: Precision, Innovation, and Why It Matters When you think of Florida, manufacturing might not be the first thing that comes to mind—but maybe it should. The Sunshine State is home to some of the most skilled Metal Stamping Companies in...

shaped extrusion machining

Shaped Extrusion Machining in Florida: Precision, Innovation, and Expertise In the heart of Florida’s thriving manufacturing sector, shaped extrusion machining has emerged as a cornerstone of modern industrial design. This process combines the versatility of extrusion...

Punching Holes in Aluminum Extrusions

Punching Holes in Aluminum Extrusions: Custom Solutions for Florida Industries Aluminum extrusions are the backbone of modern manufacturing, offering lightweight strength and versatility for industries ranging from construction to aerospace. But shaping these...

Shaped Extrusion Punching

Shaped Extrusion Punching in Florida: Precision, Customization, and Innovation Florida’s manufacturing and construction industries thrive on precision-engineered metal components. Shaped extrusion punching plays a pivotal role in creating functional and durable...

What you should know before CNC production machining

Florida’s thriving manufacturing sector relies heavily on precision and efficiency, making CNC production machining a cornerstone of industries like aerospace, automotive, and medical device manufacturing. Whether you’re a business owner or an aspiring machinist,...

General Stamping in Florida

General Stamping in Florida: Precision, Innovation, and 50+ Years of Excellence In Florida’s thriving manufacturing sector, General Stamping plays a pivotal role in creating components for industries ranging from aerospace to automotive. At the heart of this industry...

Call us today

or

Precision Aluminum Extrusion Punching & Machining | Dock Ladders, FDOT Bullet Rail, Handrails & Metal Stampings

Discover precision in aluminum extrusion punching and machining for high-quality dock ladders, FDOT Bullet Rail systems, and Bullet Rail clamps. Our expertise extends to channel punching handrails and machining aluminum tubing, ensuring durability and reliability. Specializing in production metal stampings, we deliver tailored solutions for industrial and architectural needs. Trust us for superior craftsmanship and innovative designs in aluminum fabrication.