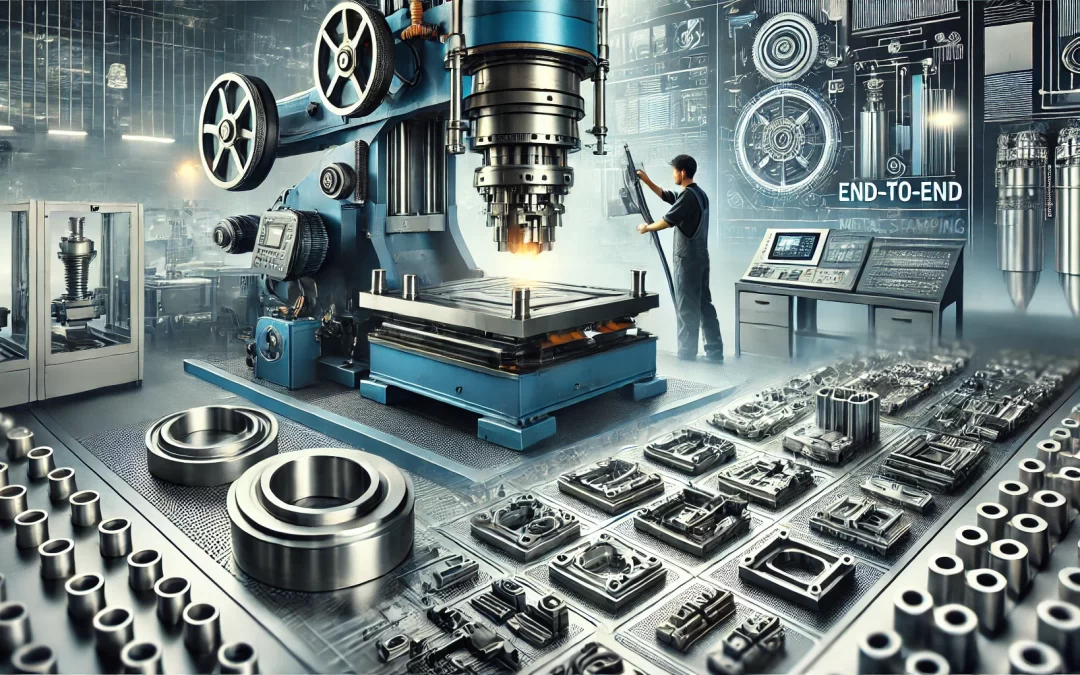

End-to-End Metal Stamping Solutions for Your Manufacturing Needs in Milton, Florida

Milton, Florida, is a thriving hub for industrial innovation, and manufacturers in the region rely on metal stamping to produce high-quality components for diverse industries. From automotive to aerospace, the demand for precision-engineered stamped parts continues to grow. This article explores the importance of end-to-end metal stamping solutions and how they address modern manufacturing challenges.

The Need for End-to-End Metal Stamping Solutions

Modern manufacturing requires agility, precision, and scalability. Companies often face challenges like fragmented workflows, inconsistent part quality, and delays due to working with multiple vendors. End-to-end metal stamping solutions eliminate these pain points by offering a seamless process—from design to delivery. By integrating material selection, tooling, production, and logistics under one roof, businesses in Milton, FL, can reduce costs, accelerate timelines, and maintain strict quality standards.

What is the Scope of Metal Stamping Services?

Metal stamping encompasses a wide range of processes, including blanking, punching, bending, and coining. These services cater to industries requiring heavy machinery components, electrical enclosures, automotive brackets, and more. A full-service provider in Milton, FL, will handle:

- Custom design and prototyping

- High-volume production runs

- Aluminum extrusion punching and forming

- Secondary finishing operations

This versatility ensures clients receive tailored solutions for both simple and complex projects.

Key Components of End-to-End Metal Stamping

1. Material Selection and Engineering Expertise

Choosing the right material is critical for durability and performance. Expert providers in Milton, FL, work with metals like stainless steel, copper, and aluminum. For instance, aluminum extrusion punching is ideal for lightweight, corrosion-resistant parts. Engineers collaborate with clients to select materials that balance cost, strength, and manufacturability.

2. Advanced Tooling and Die Design

Precision tooling is the backbone of metal stamping. Advanced CAD software and simulation tools enable the creation of high-performance dies. Prototyping ensures dies meet specifications before mass production, reducing errors and waste.

3. Precision Control in Manufacturing

Consistent part quality is achieved through Statistical Process Control (SPC). Real-time monitoring and automated systems maintain tight tolerances (±0.001 inches) for critical heavy machinery components.

4. High-Volume Production and Scalability

Local Milton, FL, facilities leverage automated presses and robotics to handle large orders efficiently. Scalable solutions allow businesses to adjust production volumes without compromising lead times.

5. Value-Added Secondary Operations

Post-stamping services like plating, powder coating, and welding add functionality and aesthetics to the stamped parts. Integrated secondary operations reduce handling and speed up delivery.

6. Supply Chain and Logistics Management

End-to-end providers manage everything from raw material sourcing to final-mile delivery. Milton’s strategic location near major highways and ports ensures timely distribution across the U.S.

Why Choose Milton, FL, for Your Metal Stamping Needs?

Milton’s manufacturing ecosystem combines skilled labor, cutting-edge technology, and robust infrastructure. Providers here specialize in aluminum extrusion punching and heavy machinery components, delivering solutions that meet ISO and AS9100 standards. By partnering with a local expert, you gain:

- Faster turnaround times

- Reduced transportation costs

- Direct access to engineering support

Built Points: Advantages of End-to-End Metal Stamping

- Single-source accountability for design, production, and logistics

- Enhanced part quality through Statistical Process Control

- Cost savings via optimized material usage and reduced waste

- Scalability to meet fluctuating demand

- Compliance with industry-specific certifications

FAQs About Metal Stamping in Milton, FL

Q: What industries benefit from metal stamping?

A: Automotive, aerospace, construction, and electronics rely on stamped parts for components like brackets, panels, and connectors.

Q: How does Statistical Process Control improve quality?

A: SPC monitors production in real time, identifying deviations early to ensure consistent part quality.

Q: Can you handle custom designs for heavy machinery components?

A: Yes. Advanced tooling and engineering expertise allow customization for unique applications.

Q: What materials are used in aluminum extrusion punching?

A: Aluminum alloys (e.g., 6061, 6063) are common for their strength-to-weight ratio and corrosion resistance.

Conclusion

For manufacturers in Milton, FL, end-to-end metal stamping solutions offer a competitive edge. By integrating material science, precision tooling, and scalable production, businesses can achieve faster time-to-market, superior part quality, and cost efficiency. Whether you need aluminum extrusion punching for lightweight parts or durable heavy machinery components, partnering with a local expert ensures your project’s success from concept to completion.

Contact us today to discuss your metal stamping needs and discover how Milton’s manufacturing expertise can elevate your operations.