Florida Aluminum Machining & FDOT Rail Solutions

Production Metal is a supply chain partner for metals and plastics manufactured components for the Hurricane shutter industry, boat tower and boat lift manufacturers as well as FDOT handrail and bike and pedestrian guardrail components. We develop and build punching equipment for the tracking systems used in solar fields. We also offer general machining services for local industrial manufacturing and machinery maintenance.

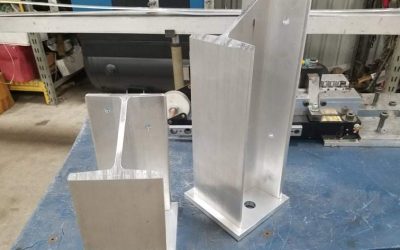

In-House Ability

Production Metal will work with you towards the design and development of your prototype and as a trusted partner for your supply chain manufacturing requirements. We offer value-added secondary operations of machining, punching, forming, and welding as well as general progressive stamping and CNC production. Our machining department designs and builds tooling to punch the flange and web of steel H beams used in the solar field tracking systems.

Our design staff works with the following formats DXF, DWG, IGS …

TOP QUALITY

Quality control, product improvement and customer involvement are the key forces behind our continued growth as we strive to manufacture products that exceed your expectations

Processing Capability of 30ft.

Processing Aluminum extrusion of 20 – 42 feet is one of our specialties.

With multiple CNC Mill and Punch presses fitted with accurate and repeatable servo feed units allows continuous machining and punching

lengths of aluminum flat bar or special shaped extrusions up to 42 feet in length.

Our automated aluminum extrusion saws supply CNC Mill, CNC lathes and punch presses for volume production of cut to length product.

News

Here are some of our latest news…

Production Metal’s American-Made Excellence

Explore Production Metal’s American-made Excellence FDOT Bullet Rail, dock ladders, and aluminum extrusion machining. Partnerships & patience ensure quality. In today’s fast-paced world, businesses often prioritize speed over quality. But at Production Metal, we...

Delivering TOP QUALITY Through Precision Engineering & Customer-Centric Innovation

In an era where industrial applications demand flawless performance, TOP QUALITY isn’t just a promise—it’s a necessity. For manufacturers committed to excellence, the triad of rigorous quality control, continuous product improvement, and active customer...

Fabrication & Assembly – Transforming Raw Aluminum Extrusions into Functional Masterpieces

When an aluminum extrusion emerges from the press, it’s rarely a finished product. To meet the exacting demands of industries like automotive, construction, and aerospace, these raw profiles must undergo specialized fabrication and assembly processes. This article...

Sangiacomo Punch Press

Sangiacomo Punch Press automated for punching aluminum extrusions is nearing completion Introduction: Revolutionizing Sangiacomo Punch Press Aluminum Extrusion Punching The manufacturing world is buzzing with excitement as Sangiacomo’s newest automated punch...

Print Wheel & Supporting Carriage for Automatic Wire Stenciling in Cable Manufacturing

Introduction: Precision Marking in Cable Production In the fast-paced world of cable manufacturing, clear and durable wire identification is critical. Automatic wire stenciling systems, powered by print wheels and supporting carriages, ensure cables are marked with...

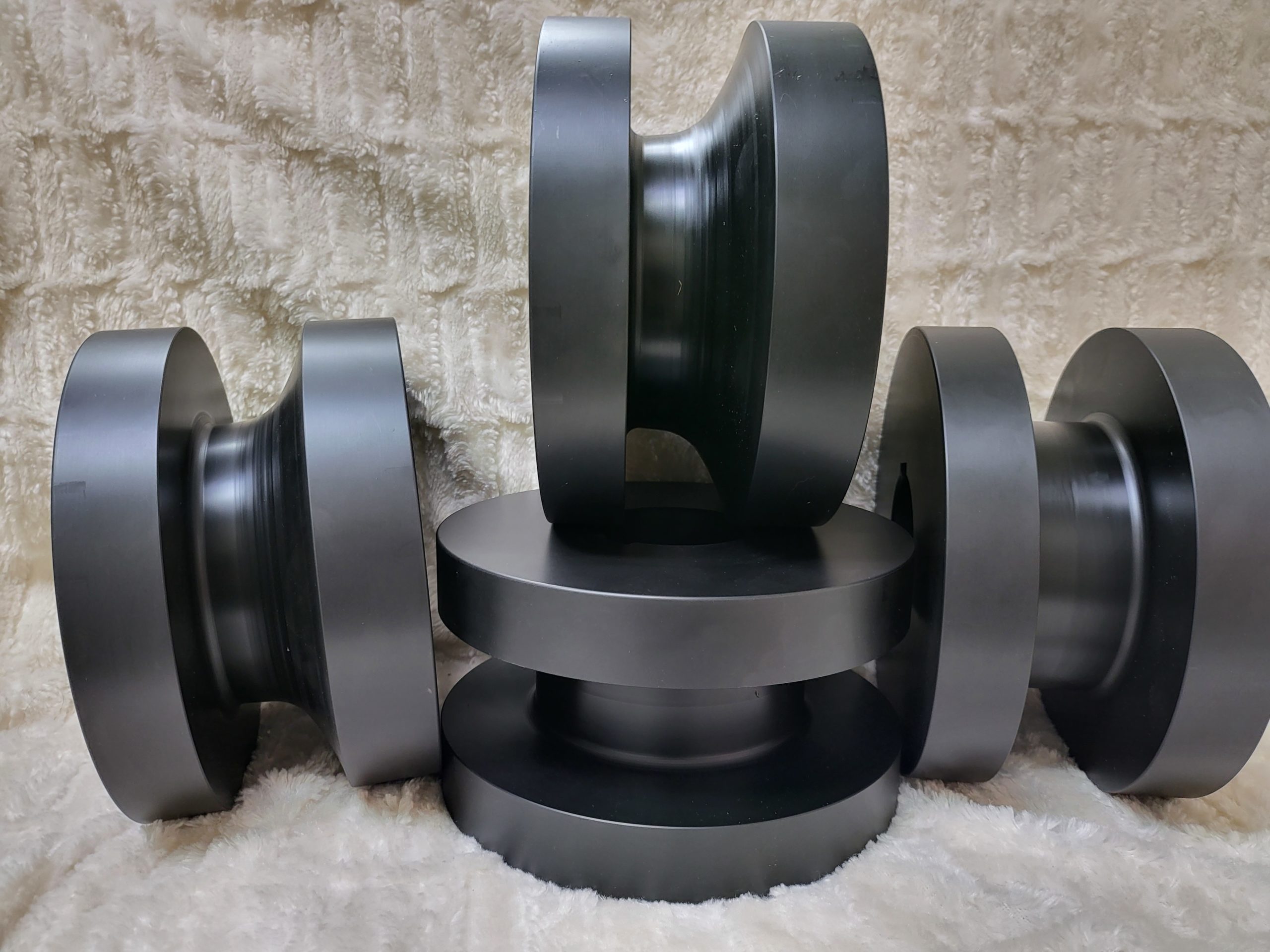

Roller wheels for Eastern Metal D Shape Boat tower Tube/Frame

Roller wheels are critical components in marine systems, especially for Eastern Metal’s D-Shape boat tower tubes and frames. Designed to support smooth movement and reduce friction, these rollers ensure safe boat launching, retrieval, and storage. Built to withstand...

Aluminum Extrusion Punching

Aluminum extrusion punching and tooling are essential processes in modern manufacturing, enabling the creation of precise, durable, and lightweight components for industries ranging from automotive to construction. This article explores how these techniques work,...

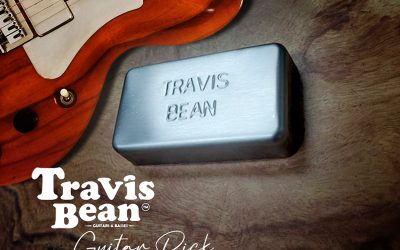

Travis Bean Guitar

Kevin Burkett of the Electrical Guitar Company worked with us to resurrect the pickup cover for the Travis Bean Guitar. Introduction: A Legendary Collaboration The Travis Bean guitar, renowned for its aluminum neck and sustain-rich tone, has long been a holy grail for...

FDOT Bullet Rail – Precision-Cut & Machined to Perfection

In the world of transportation infrastructure, precision and reliability are non-negotiable. The FDOT Bullet Rail stands out as a critical component for rail systems, engineered to meet stringent safety and performance standards. By combining advanced CNC...

Call us today

or

Precision Aluminum Extrusion Punching & Machining | Dock Ladders, FDOT Bullet Rail, Handrails & Metal Stampings

Discover precision in aluminum extrusion punching and machining for high-quality dock ladders, FDOT Bullet Rail systems, and Bullet Rail clamps. Our expertise extends to channel punching handrails and machining aluminum tubing, ensuring durability and reliability. Specializing in production metal stampings, we deliver tailored solutions for industrial and architectural needs. Trust us for superior craftsmanship and innovative designs in aluminum fabrication.

Production Metal Stampings: Florida’s Partner for Precision Aluminum Extrusion & Machining

In Florida, where hurricanes, coastal infrastructure, and marine industries demand durability and precision, Production Metal stands out as a leading supply chain partner for Metal Stampings and Aluminum Extrusion Punching & Machining. From hurricane shutters to FDOT-compliant handrails, their expertise in shaped extrusion punching and shaped extrusion machining ensures high-quality, cost-effective solutions for industries across the Sunshine State.

What Are Production Metal Stampings?

Production Metal Stampings involve shaping flat metal sheets or aluminum extrusions into specific components using dies and presses. This process is vital for creating parts like brackets, panels, and frames with speed and accuracy. At Production Metal, advanced techniques like shaped extrusion punching—a method to cut precise holes or patterns into aluminum extrusions—ensure components meet strict industry standards.

Key Services & Solutions

1. Shaped Extrusion Punching & Machining

Shaped extrusion punching is the go-to method for secondary processing of aluminum extrusions. It involves using custom dies to punch holes, slots, or intricate designs into extruded parts. Benefits include:

-

Speed: Ideal for high-volume production.

-

Precision: Consistent results for complex geometries.

-

Cost-Effective: Reduces waste and labor costs.

Paired with shaped extrusion machining (refining parts via CNC milling or drilling), this process delivers components ready for assembly, such as FDOT Bullet Rail segments or Dock Ladders.

2. Extrusion Machining Centers

An extrusion machining center is a specialized machine that cuts, drills, and shapes raw aluminum extrusions into finished products. Production Metal uses these centers to craft:

-

Boat Towers & Lifts: Corrosion-resistant parts for Florida’s marine industry.

-

Solar Tracking Systems: Durable components for renewable energy fields.

-

FDOT Handrails & Guardrails: Safety-compliant designs for public infrastructure.

3. Custom Tooling & Metal Stampings

From hurricane shutter brackets to Metal Stampings for machinery, Production Metal designs and builds custom punching equipment tailored to client needs. Their services include:

-

Prototyping and small-batch production.

-

High-tolerance machining for industrial equipment.

-

Affordable, low-cost parts without compromising quality.

Applications in Florida’s Key Industries

Hurricane Shutters

Florida’s storm-prone climate requires robust hurricane shutter systems. Production Metal supplies precision Aluminum Extrusion Punching & Tooling to create lightweight yet durable shutter frames and hardware.

Marine & Boating

From Dock Ladders to boat lift components, their shaped extrusion machining ensures parts withstand saltwater corrosion and heavy use.

Infrastructure & Solar Energy

-

FDOT Bullet Rail and pedestrian guardrails for safe highways.

-

Solar field tracking systems built for longevity in harsh environments.

General Manufacturing

Production Metal supports local industries with general machining services, including machinery maintenance and custom fabrications.

Why Choose Production Metal?

Expertise in Aluminum Extrusion Punching & Machining

With decades of experience, they understand the nuances of working with aluminum grades like 6061 and 6063, balancing strength, malleability, and corrosion resistance.

Advanced Technology

State-of-the-art extrusion machining centers and CNC equipment ensure precision for complex projects.

Cost-Effective Solutions

As a Low-Cost Parts Company in the USA, they optimize production to reduce expenses without sacrificing quality.

Local & Reliable

Based in Milton, USA, they serve Florida’s industries with fast turnaround times and personalized support.

FAQs

Q: What’s the difference between stamping and extrusion?

A: Stamping shapes flat metal using dies, while extrusion forces aluminum through a mold to create long, uniform profiles.

Q: How much does an aluminum extrusion tool cost?

A: Tooling costs vary based on complexity but typically range from $1,500 to $10,000. Production Metal offers cost-effective solutions for small and large batches.

Q: What’s the best aluminum grade for extrusion?

A: 6061 and 6063 are popular for their balance of strength and workability. 6061 is ideal for structural parts, while 6063 offers smoother surfaces for finishes.

Q: What finishes do you offer for aluminum extrusions?

A: Options include anodizing, powder coating, and mill finish, depending on aesthetic and durability needs.

Q: Why is Production Metal considered a top extrusion company?

A: Their blend of advanced technology, industry-specific expertise, and commitment to affordability makes them a leader in Florida.

Conclusion

For industries in Florida—from marine to infrastructure—Production Metal delivers precision, durability, and value through Aluminum Extrusion Punching & Machining and Metal Stampings. Whether you need hurricane shutter components, FDOT Bullet Rail, or custom tooling, their expertise in shaped extrusion punching ensures your project meets the highest standards.

Ready to Partner with the Best? Contact Production Metal today for tailored solutions that withstand Florida’s toughest challenges.