Shaped Extrusion Machining in Florida: Precision, Innovation, and Expertise

In the heart of Florida’s thriving manufacturing sector, shaped extrusion machining has emerged as a cornerstone of modern industrial design. This process combines the versatility of extrusion with the precision of machining to create complex, high-performance components. Leading this innovation is ProductionMetal.net, a Florida-based company renowned for delivering high-precision solutions to OEMs worldwide. In this guide, we’ll break down the fundamentals of shaped extrusion machining, its applications, and why ProductionMetal.net is a trusted partner for industries across the globe.

What Is Shaped Extrusion Machining?

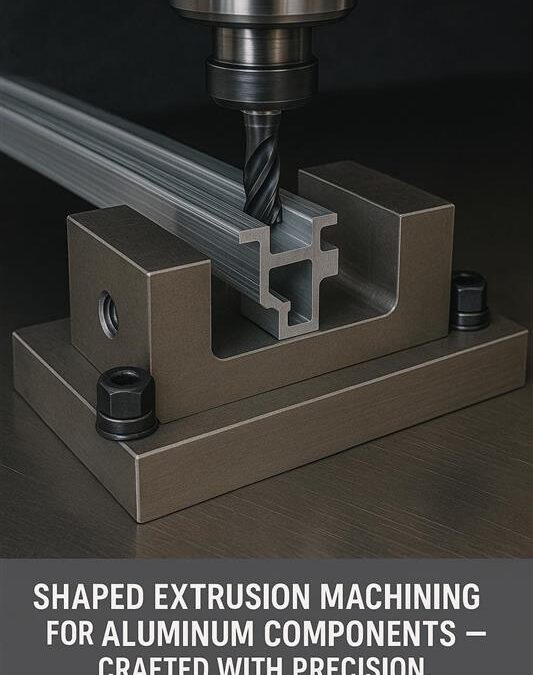

Shaped extrusion machining refers to a two-step process:

-

Extrusion: A material (typically aluminum or other metals) is forced through a custom-designed die to create a continuous profile with a specific cross-sectional shape.

-

Machining: The extruded profile undergoes CNC milling, drilling, or cutting to refine its dimensions, add features like holes or threads, and meet exact tolerances.

This hybrid method allows manufacturers to produce lightweight, durable, and intricately designed parts for industries ranging from aerospace to construction.

Why Choose ProductionMetal.net for Shaped Extrusion Machining?

As a leader in the aluminum extrusion industry, ProductionMetal.net (based in Florida, USA) stands out for its:

-

State-of-the-Art Facilities: Equipped with advanced extrusion machining centers capable of handling large-scale and custom orders.

-

Expertise: Decades of experience in Understanding Extrusion Machining processes and material science.

-

Custom Solutions: Tailored Aluminum Extrusion Machining Products for automotive, aerospace, and renewable energy sectors.

-

Global Reach: Serving progressive OEMs worldwide while maintaining a strong foothold in Florida’s industrial ecosystem.

Visit https://productionmetal.net/ to explore their capabilities.

A Beginner’s Guide to Understanding Extrusion Machining

1. Is Extrusion a Shaping Process?

Yes! Extrusion machining is an assembling process that shapes materials by pushing them through a die. Think of it like squeezing toothpaste from a tube—the die determines the final shape, whether it’s a simple rod or a multi-channel heat sink.

2. What Metals Can Be Shaped by Extrusion?

-

Aluminum: The most common due to its lightweight, corrosion resistance, and malleability.

-

Copper: Used for electrical components.

-

Steel and Titanium: For high-strength applications.

3. What Shapes Can Be Made Using Extrusion?

From angles and T-slots to hollow tubes and intricate automotive trim, extrusion supports endless profiles. ProductionMetal.net specializes in creating complex geometries that meet strict industry standards.

4. What Is an Extrusion Machine?

An extrusion machining center is a system that heats metal billets, forces them through a die, and cools the extruded profile. Modern centers, like those at ProductionMetal.net, integrate CNC machining for seamless post-processing.

Applications of Shaped Extrusion Machining

1. Aerospace

-

Lightweight structural components.

-

Heat-resistant engine parts.

2. Automotive

-

Chassis frames, trim, and battery housings for EVs.

3. Construction

-

Window frames, solar panel rails, and building supports.

4. Consumer Electronics

-

Heat sinks, enclosures, and connector housings.

By leveraging the aluminum extrusion industry’s advancements, ProductionMetal.net delivers parts that enhance performance and reduce costs.

ProductionMetal.net’s Cutting-Edge Extrusion Machining Centers

Based in Florida, USA, ProductionMetal.net has developed proprietary extrusion machining centers that streamline production. Their facilities feature:

-

CNC Machining Integration: For precision cutting, drilling, and finishing.

-

Multi-Axis Capabilities: To handle complex angles and contours.

-

Quality Control Systems: Ensuring every product meets ISO and industry-specific certifications.

These innovations allow the company to produce high-tolerance components faster and more efficiently than traditional methods.

Aluminum Extrusion Machining Products: Versatility Redefined

ProductionMetal.net’s Aluminum Extrusion Machining Products cater to diverse needs:

-

Custom Profiles: Tailored to client specifications.

-

High-Strength Alloys: For demanding environments.

-

Surface Treatments: Anodizing, powder coating, or polishing for enhanced durability and aesthetics.

Whether it’s a prototype or a mass-production order, their solutions balance cost-efficiency with uncompromised quality.

FAQs About Shaped Extrusion Machining

Q: Is extrusion machining suitable for small-scale projects?

A: Absolutely! ProductionMetal.net offers scalable solutions, from prototypes to large batches.

Q: How does aluminum benefit extrusion machining?

A: Aluminum’s malleability, lightweight nature, and recyclability make it ideal for shaped extrusion machining.

Q: What industries rely most on extrusion machining?

A: Aerospace, automotive, construction, and renewable energy sectors are top users.

Q: Can extrusion create hollow shapes?

A: Yes—using specialized dies, hollow profiles like tubes or channels are easily achievable.

Conclusion

Shaped extrusion machining is revolutionizing how industries design and manufacture components. For businesses seeking precision, efficiency, and innovation, ProductionMetal.net—Florida’s premier provider—delivers end-to-end solutions backed by cutting-edge extrusion machining centers and deep expertise in the aluminum extrusion industry and Shaped Extrusion Punching.

Ready to Elevate Your Manufacturing Process? Partner with ProductionMetal.net to transform your ideas into high-performance, custom-engineered products.